Welcome to Our Company -

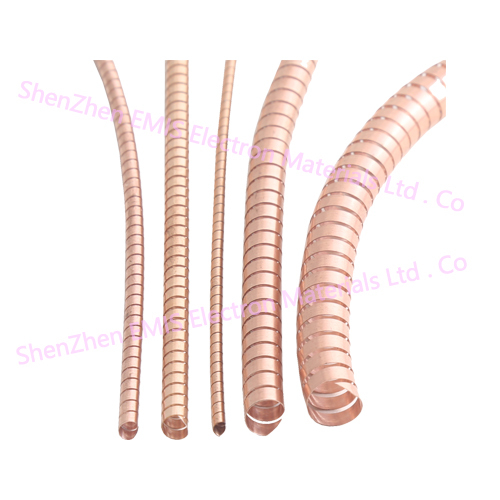

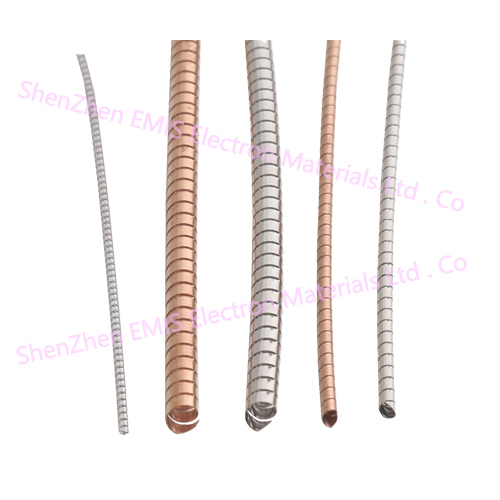

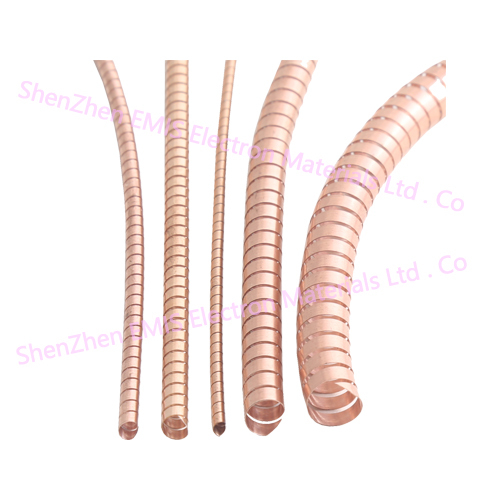

BeCu Spiral Tube

5.2 USD ($)/Meter

Product Details:

- Pressure Ratings Not rated for fluid pressure

- Surface Treatment Polished or tinned

- Operating Temperature -60C to 200C (approx)

- Automation Grade Manual or custom

- Used For Protecting wires and cables, electrical shielding, spring contacts

- Load Capacity Varies by size and configuration

- Features Flexible, durable, non-magnetic, fatigue and wear resistant

- Click to view more

X

BeCu Spiral Tube Price And Quantity

- 100 Meter

- 5.2 USD ($)/Meter

- 5.20 - 8.50 USD ($)/Meter

BeCu Spiral Tube Product Specifications

- Not rated for fluid pressure

- Beryllium Copper (BeCu)

- Polished or tinned

- High strength, excellent electrical & thermal conductivity, corrosion resistant

- Electrical, electronics, telecommunications, aerospace

- Manual or custom

- -60C to 200C (approx)

- Protecting wires and cables, electrical shielding, spring contacts

- New

- Spiral Tube

- Flexible, durable, non-magnetic, fatigue and wear resistant

- Varies by size and configuration

- Custom as per application

Product Description

BeCu Spiral Tube is the basis for all of our unique high shielding EMI gasketing solutions. The spiral iswound out of spring temper beryllium copper for excellent spring memory and compression set resistance. The spiral is

tin plated for superior conductivity and shielding properties.The edge plated version exhibits excellent corrosion

resistance against aluminum when exposed to humid or salt-fog environments.

High Strength and Superior Conductivity

Manufactured from beryllium copper, the spiral tube exhibits impressive tensile strength (11001400 MPa), ensuring robust protection and longevity. Its inherent electrical and thermal conductivity makes it particularly suitable for environments demanding reliable signal transmission and heat dissipation. The tubes Rockwell B80B100 hardness and corrosion resistance uphold performance even in challenging conditions.

Customizable to Suit Diverse Applications

Our BeCu Spiral Tubes offer flexibility in dimensions, length, connectors, and packaging, accommodating specific client needs across diverse industries. Whether used for wire protection, shielding, or spring contacts, its adaptable design ensures seamless integration into custom installations. Optional surface treatments such as polishing or tinning are available for enhanced utility and appearance.

Compliance and Quality Assurance

Every BeCu Spiral Tube meets RoHS and REACH regulations, ensuring safety and environmental stewardship. Supplied in coil, wrapped, or bulk packaging, each product is delivered in optimal condition, ready for immediate implementation in your electrical or mechanical systems. We uphold strict quality standards throughout manufacturing and exporting processes.

FAQs of BeCu Spiral Tube:

Q: How can the BeCu Spiral Tube be customized for specific applications?

A: The BeCu Spiral Tube can be tailored in terms of tube diameter (1 mm to 10 mm), wall thickness (0.3 mm to 2 mm), length (up to 5 meters or as needed), and connector types at both ends. Surface finishes and packaging options are also customizable to fit project specifications.Q: What are the primary uses of the BeCu Spiral Tube?

A: This spiral tube is primarily used for protecting wires and cables, providing electrical shielding, acting as spring contacts, and serving in various industries like electronics, telecommunications, aerospace, and electrical systems.Q: Where is the BeCu Spiral Tube typically installed or utilized?

A: You will find the BeCu Spiral Tube integrated into cabling systems, enclosures, and devices in electrical, electronic, telecom, and aerospace environmentsanywhere flexible, durable, and conductive protection for wires or cables is required.Q: What is the process for ordering a custom BeCu Spiral Tube?

A: Clients can specify required parameters such as diameter, wall thickness, length, connector type, surface treatment, and packaging. Our team then manufactures and supplies tubes tailored to these specifications, ensuring precise alignment with project needs.Q: Which benefits do BeCu Spiral Tubes provide over conventional materials?

A: Compared to conventional tubing, BeCu Spiral Tubes offer superior mechanical strength, fatigue resistance, excellent electrical and thermal conductivity, non-magnetic performance, and resilience against corrosion, making them ideal for demanding applications.Q: Is the BeCu Spiral Tube suitable for both manual and automated installations?

A: Yes, the spiral tube is designed for either manual or custom automation integration thanks to its flexible construction and optional connector designs. This versatility makes installation easy in a wide range of applications.Q: What international standards does the BeCu Spiral Tube comply with?

A: Our BeCu Spiral Tubes adhere to RoHS and REACH standards, ensuring environmentally responsible production and safe use in regulated markets worldwide.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese